Hot Stamping

We help you gain a competitive advantage with our Hot Stamping processes. Be inspired by individual, creative designs and optimally defined production processes in Hot Stamping. Hot Stamping is particularly suitable for special designs, including outdoor use or large series. We use it to optimally implement the requirements of our customers.

Hot Stamping PERFORMANCE+

This process is especially suitable for complex geometries. The components are inserted and decorated in a fully automatic two-part tool. Advantages of PERFORMANCE+: The material does not need to be preheated, so the process uses less energy than the classic hot stamping process.

Vertical stamping and roller embossing

For high-level decoration of flat or curved surfaces, rely on the economical Hot Stamping process for unique effects, whether full-surface or partial. The decoration is applied with extreme precision using vertical stamping or roller embossing. Our designs specially created for Hot Stamping give your products a special radiance and resistance to external influences. Recycled materials can also be excellently finished. Hot Stamping opens up a wide range of design options, including environmentally friendly metallisation, which can be achieved without the use of harmful chrome VI. Unleash the full potential of your surfaces!

Benefit from the many high-quality and recyclable finishing options offered by our Hot Stamping foils. For special editions or large series.

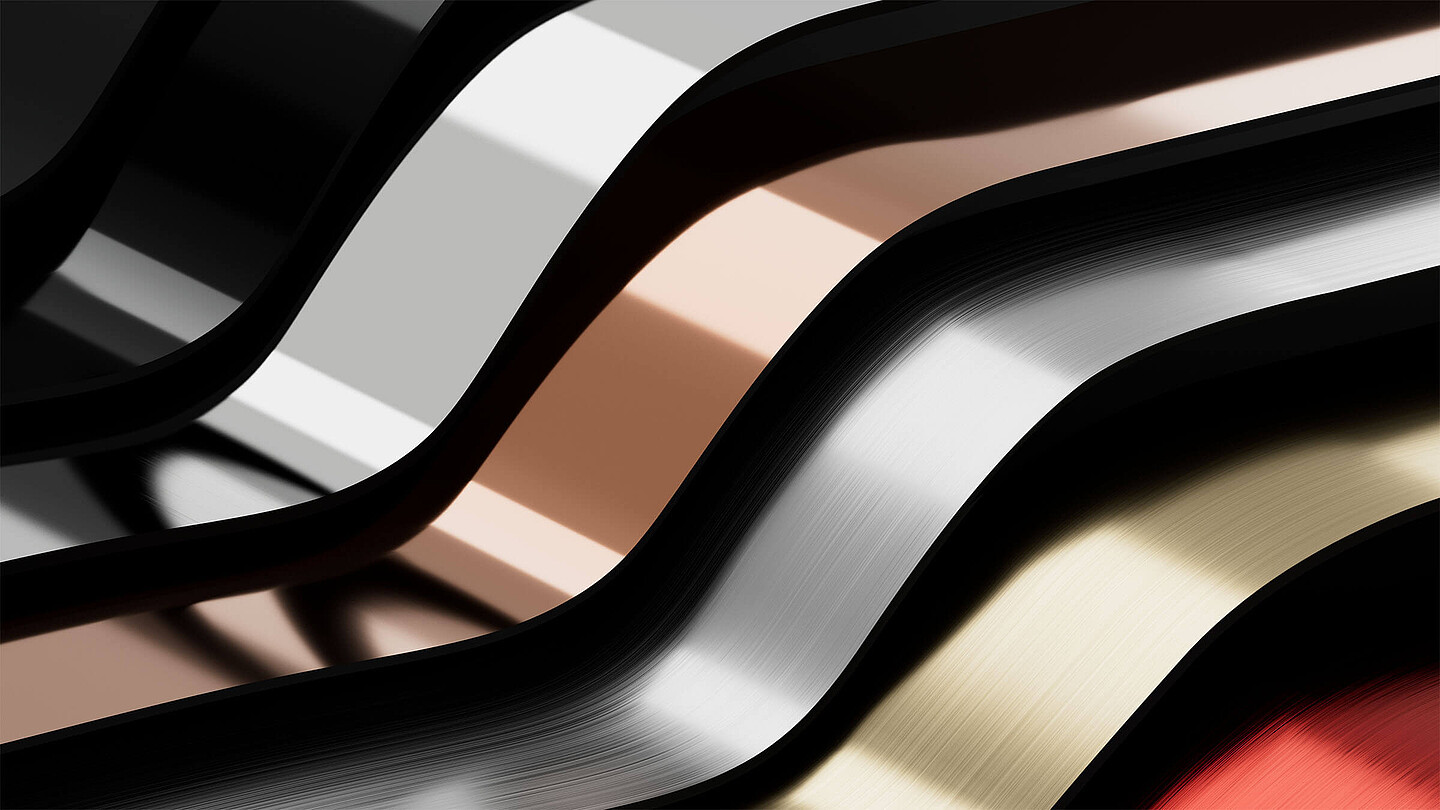

LUXOR®/ALUFIN®:

Do you want to give your surfaces a particularly luxurious and elegant touch? Then opt for our metallized finishings for decors in silver, gold, or chrome, in high-gloss, matte, or brushed variants. The properties of the coatings are precisely tailored to your requirements: In terms of edge definition, adhesion and temperature, abrasion and scratch resistance. The real advantage: The chrome plating is performed dry without any electroplating, making the process safer, more sustainable, and economical. In addition, you can also metallize parts of surfaces and work with backlighting effects - to create attractive, unique, and special plastic surfaces.

COLORIT® and UNICOLOR

Infinite color variations that stimulate the imagination and convey emotions: Impress your customers with COLORIT® and UNICOLOR. These finishes are also cost-effective and reduce the burden on people and the environment. We offer a wide range of standard colors. In addition, we develop coatings in your corporate colors or according to individual preferences.

For partial decoration, our COLORIT® range shines in all colors of the rainbow on paper, cardboard, and plastic. Choose the COLORIT® 800 series for glossy colors and COLORIT® 900 for matte colors. You can also use these coatings for tricky surfaces such as lipstick cases. They are easy to process, abrasion resistant, and provide excellent coverage.

UNICOLOR is the right choice for full-surface decoration using the roll-on process, for example, for consumer electronics products. You will be rewarded with brilliant gloss, homogeneous colors, plus scratch and abrasion resistance. The finishes can be used on a variety of substrates and processed using a variety of methods.

Hologram foils

Flat or protruding? With or without texture? With TRUSTSEAL® Lens, you can create a spatial, visual depth on labels that you can’t take your eyes off. In silver, gold, or transparent, for round or square shapes. TRUSTSEAL® SFX conjures up fascinating 3D effects on labels or stickers with an unusual depth effect and appearance. Holographic foils are real eye-catchers that your customers will remember.

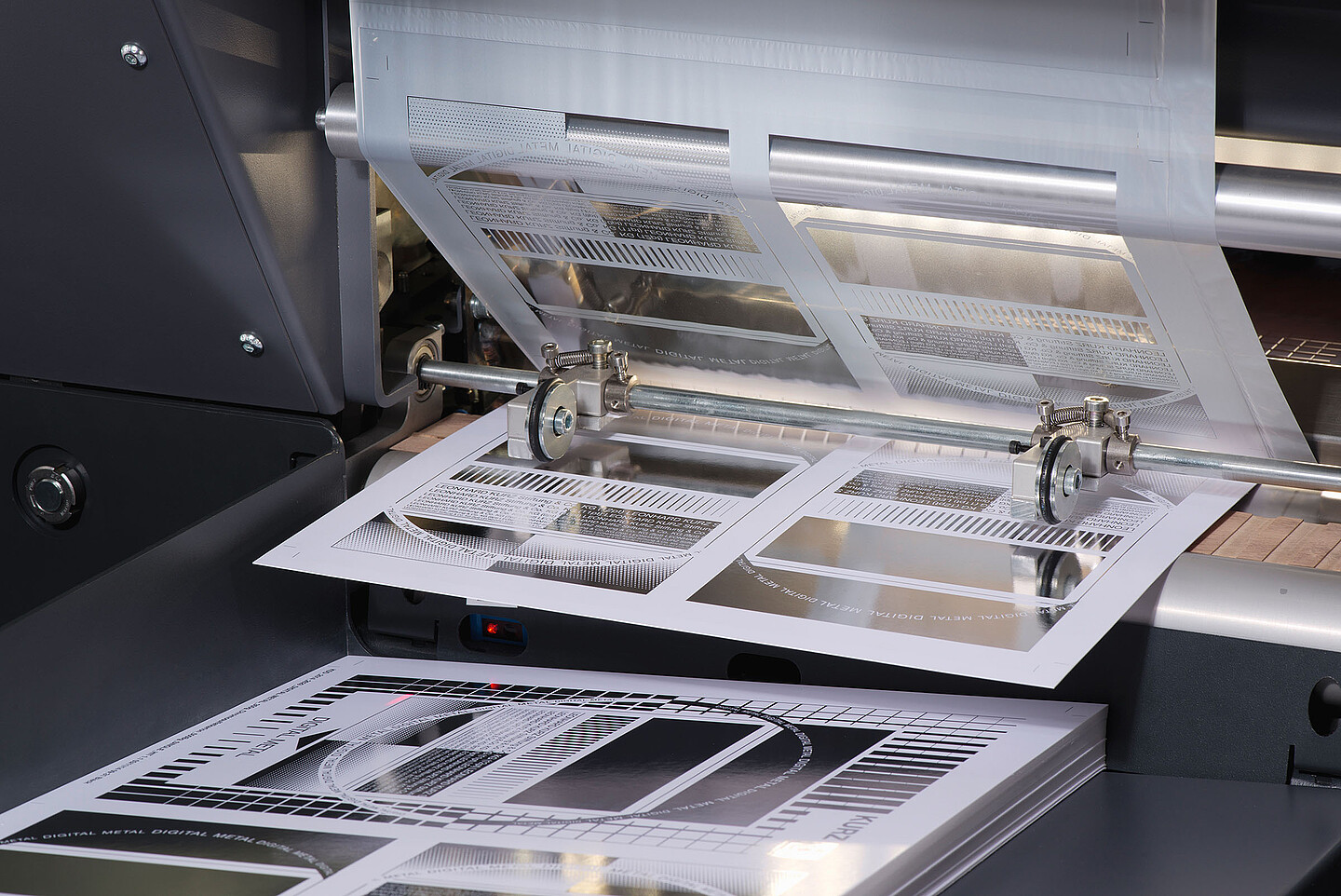

Hot Stamping foils and machines

Rely on the comprehensive expertise of the KURZ Group in a wide range of industries, and on our international development and design team. We provide everything from a single source: Hot Stamping foils and machines are perfectly matched to each other. We help you get the results you want for series production.

How you benefit when choosing to team up with KURZ:

- Large standard range of decors or custom developments. We deliver decors for your individual requirements

- Easy and quick decor changeovers. The rolls with the design can be changed in just a few easy steps

- Low-cost process, from small volumes to batch production. Drying times and elaborate set up in production are done away with

- Excellent physical and chemical durability of our coatings

- Sustainable process, safe for processors as no solvents are released

- Recyclability of plastic products remains intact despite decoration

- Recycled materials can be easily decorated

- Everything from a single source - from stamping foils to production equipment. You’ll benefit from one single point of contact