PolyTC® VarioSym

With new groundbreaking solutions, LEONHARD KURZ and its subsidiary PolyIC set new aesthetic, functional and production standards for touch control surfaces in close cooperation.

Challenge

The market for household appliances is growing, and modern products are becoming increasingly more convenient and smarter. As technology evolves, so does the way we use washing machines, microwaves, and refrigerators. Smooth surfaces, invisible shy tech design elements (black panels), touch and gesture control, and highly individual designs determine how they look. All of this presents manufacturers with new challenges. High transparency of the surfaces, color fastness, and backlighting must also be taken into account right from the start. Hygiene is another important factor, especially in kitchens and bathrooms. Frequently touched surfaces must be easy to clean on a regular basis without damaging sensors or decoration.

Goal

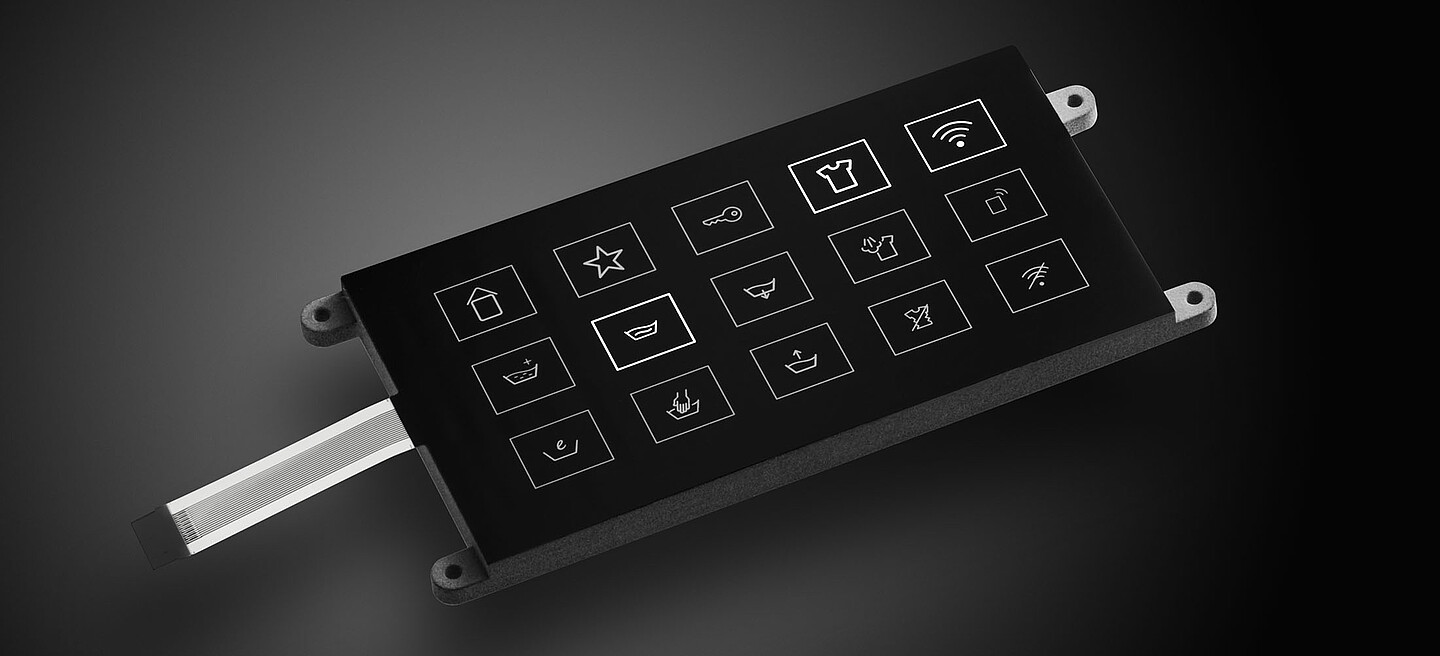

On the one hand, an innovative sensor should enable opaque decoration, but on the other hand, it should also be possible to create completely individual designs. For example, the customer should be able to flexibly choose the position of the touch buttons and have various symbols and functions displayed. The sensor should be used primarily for control panels and user interfaces in household appliances and consumer electronics.

Solution

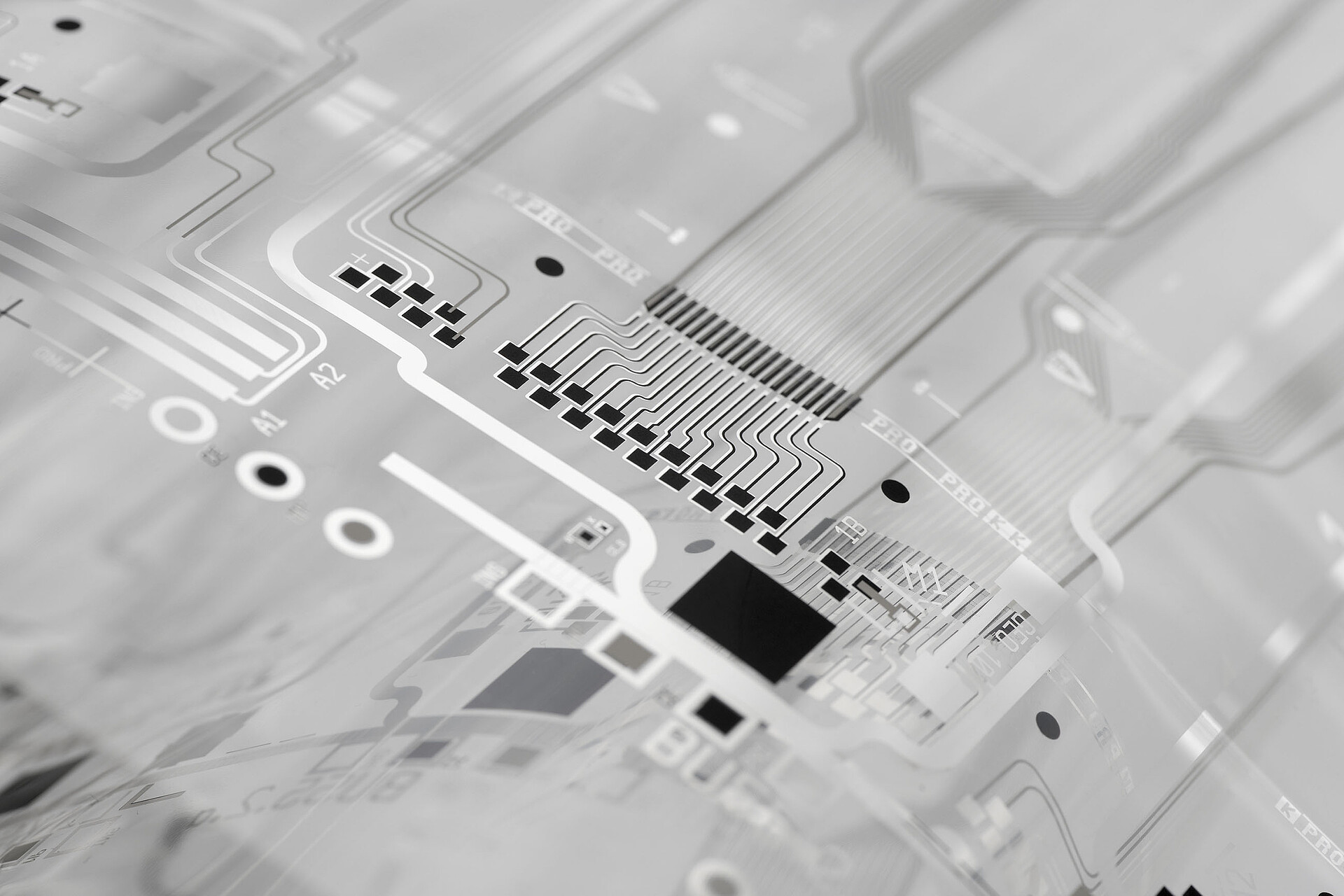

The PolyTC® VarioSym sensor from KURZ subsidiary PolyIC meets all of the above criteria. Integrated into a pioneering washing machine panel that KURZ presented at K 2022 in Düsseldorf, the PolyIC sensor impressively illustrates what a modern control panel for household appliances can look like. The revolutionary PolyTC® technology offers the highest functionality and maximum design freedom for capacitive keys, touch screens, and multi-touch sensors - even on curved and backlit surfaces.

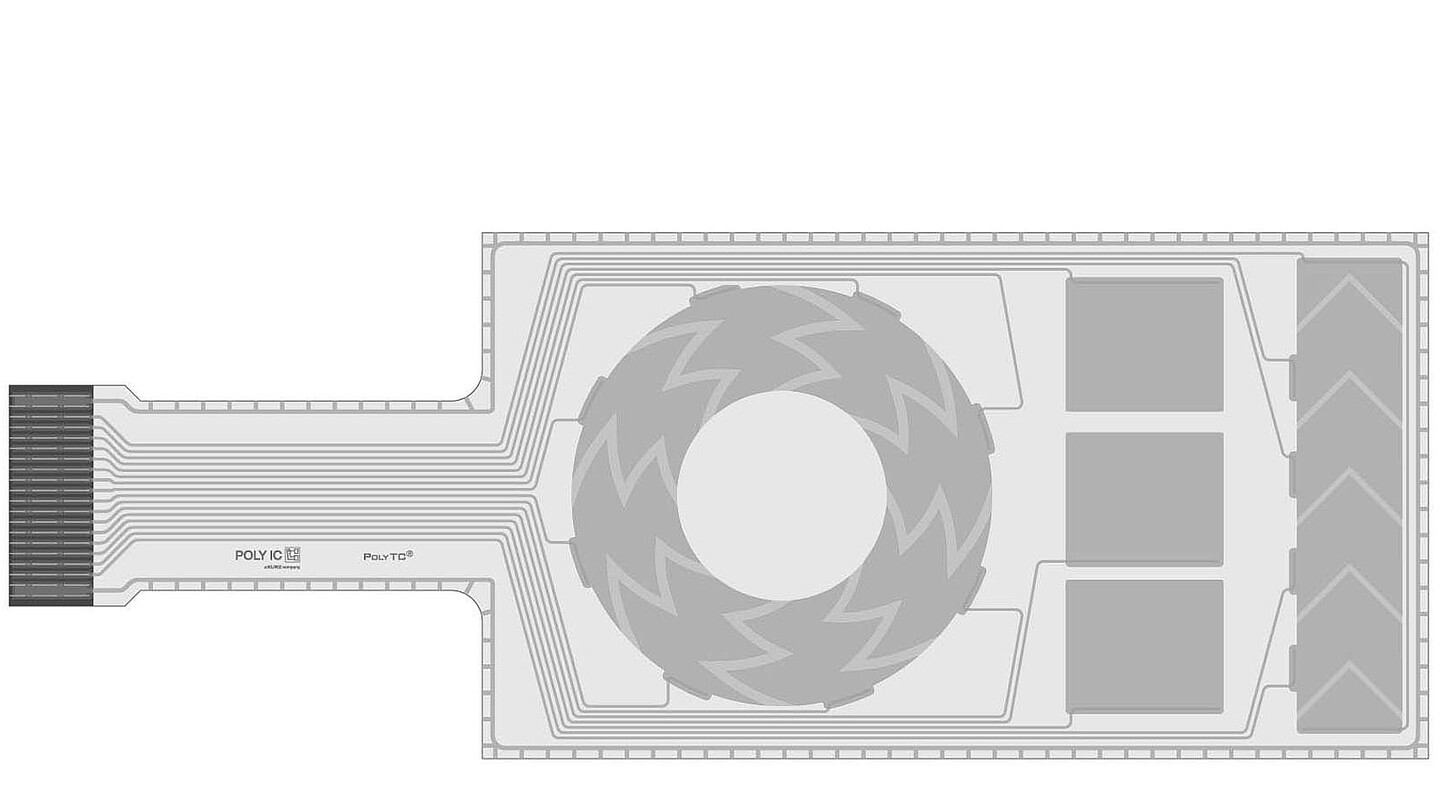

The major innovation is that the PolyTC® VarioSym sensor no longer requires all components (touch sensor, diffuser, and opaque top layer) to be applied separately. The new sensor combines all relevant technical layers in one. In contrast to conventional manufacturing processes, the PolyTC® VarioSym eliminates one component and one work step, which enables more efficient, cost-saving production. Country languages and symbols are only lasered in the very last production step, so that the sensor can be used for a wide range of devices and national languages. The fact that this step is carried out by the customers themselves, directly before the sensor is installed, provides a completely new freedom when it comes to positioning symbols and labels.

In addition, the messy presentation of 7-segment displays due to the previously high lamination tolerances is no longer a problem either. Thanks to the final high precision customization with lasers, the PolyTC® VarioSym sensor does not create any offset and therefore also no rejects.

PolyTC® VarioSym: An efficient all-rounder

PolyTC® VarioSym sensors can be used to map different functionalities - touch buttons and dial or slider functions, for example. This means that they are fully in line with the trends in the design and operation of modern household appliances and consumer electronics. In addition, they offer multiple advantages over conventional processes:

- Efficiency. Serial production with fewer work steps saves time and resources compared to traditional processes. In addition, the already high requirements for position accuracy in the overall setup can be achieved and met more easily

- Color variation. As the sensor is backlit by LEDs, different color versions are also possible

- Design freedom. The lasering of icons and letterings is extremely precise, so that even small elements and fine structures can be implemented

- Flexibility. The special structure of layers and the conductive structures make sensors very flexible, so they smoothly adapt to curved geometries as well

- Conductivity. The highly conductive metal mesh structure of PolyTC® sensors ensures that they are reliably touch-active, even through thick materials

- Flexibility. Depending on the area of application and budget, other PolyIC technologies can also be used instead of metal mesh - for example, more cost-effective PEDOT sensors

Why KURZ is the right technology partner

- KURZ is continuously developing its solutions

- The PolyTC® sensors are ‘made in Germany’

- The PolyTC® sensors allow transparent or semi-transparent (radiolucent) touch applications

- Roll-to-roll manufacture facilitates the production of higher runs in consistently high quality

- Even small runs can be realized at the price advantage of large runs

Conclusion

The PolyTC® VarioSym sensor not only fully meets the trends in the design and operation of modern household appliances and consumer electronics, but also offers many economic advantages over conventional processes. It allows for a high degree of customization, is suitable for a wide range of household appliances and consumer electronics, and ensures efficient production.