Print Mold Design (PMD)

A washing machine in the high-gloss kitchen, a refrigerator right next to a bookshelf in the living room - aesthetically sophisticated surfaces make it possible for areas of life to merge together. This poses a special challenge for the product design. Stand out with Print Mold Design (PMD) from our subsidiary BURG DESIGN. As an industry-wide solution provider for finishing, we bring together the best technologies from different industries. With our unmistakable sense for trends and innovation, your products are sure to become coveted designer pieces.

The Print Mold Design process

Print Mold Design (PMD) is related to Insert Molding technology and adds value to products.

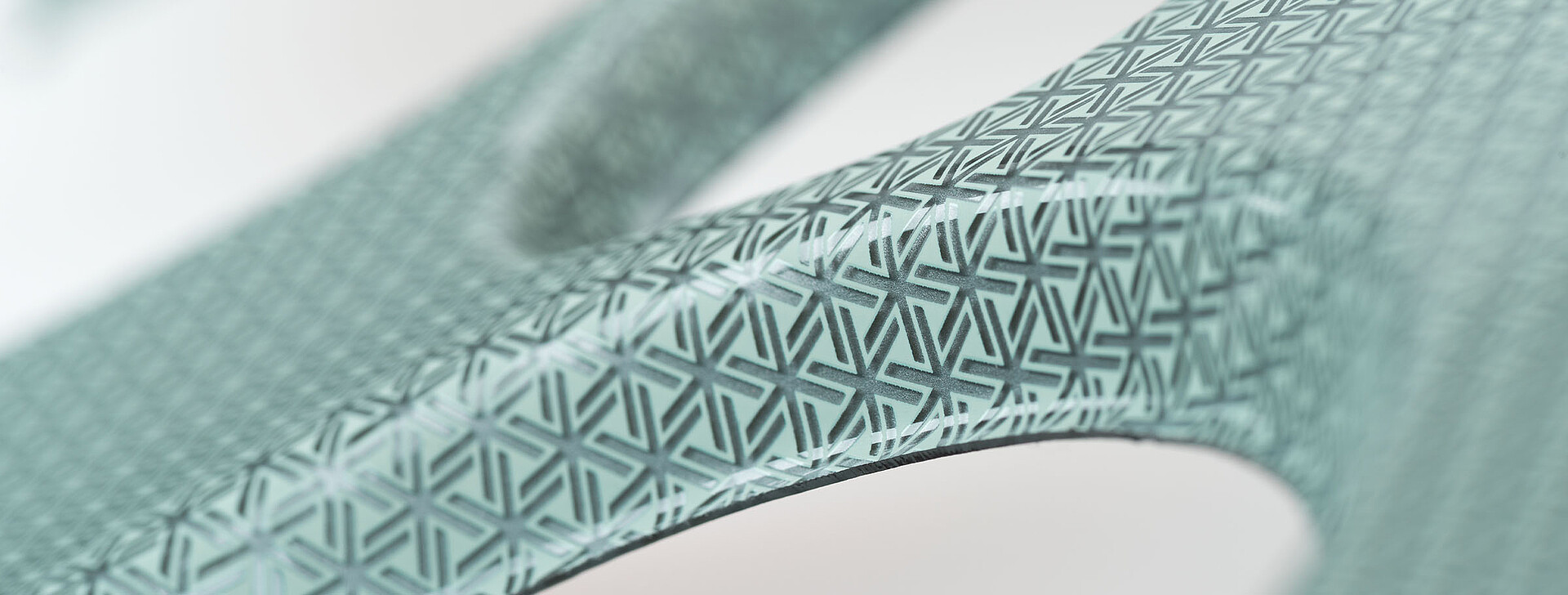

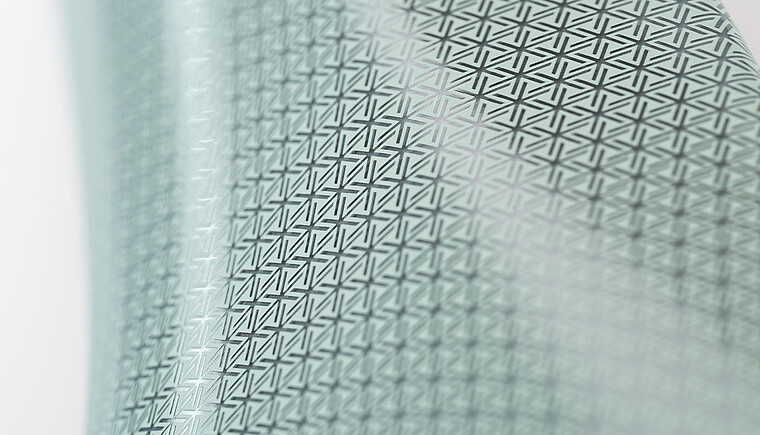

With special silk-screen printing technology, transparent plastic sheets are printed on one or both sides, color by color.

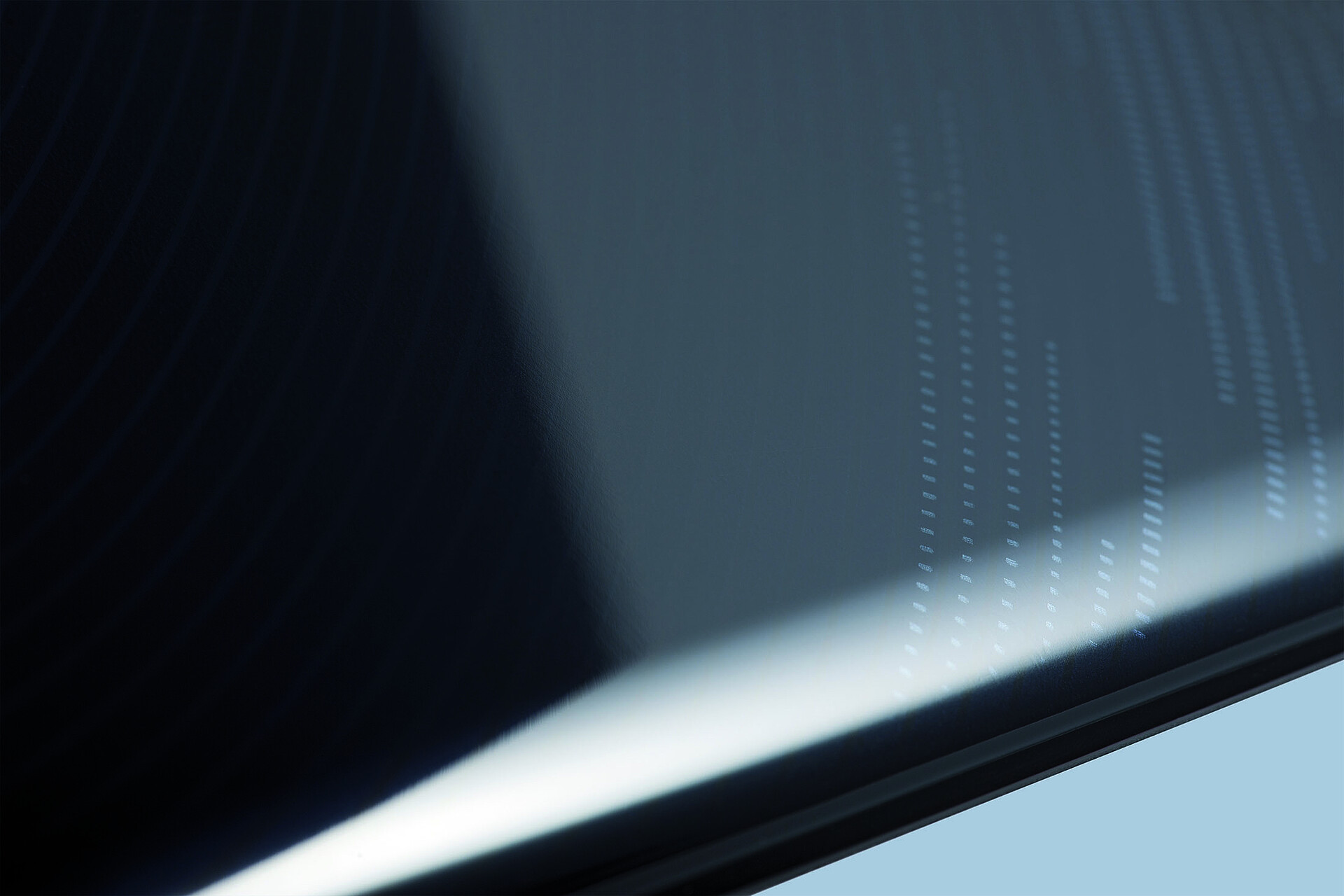

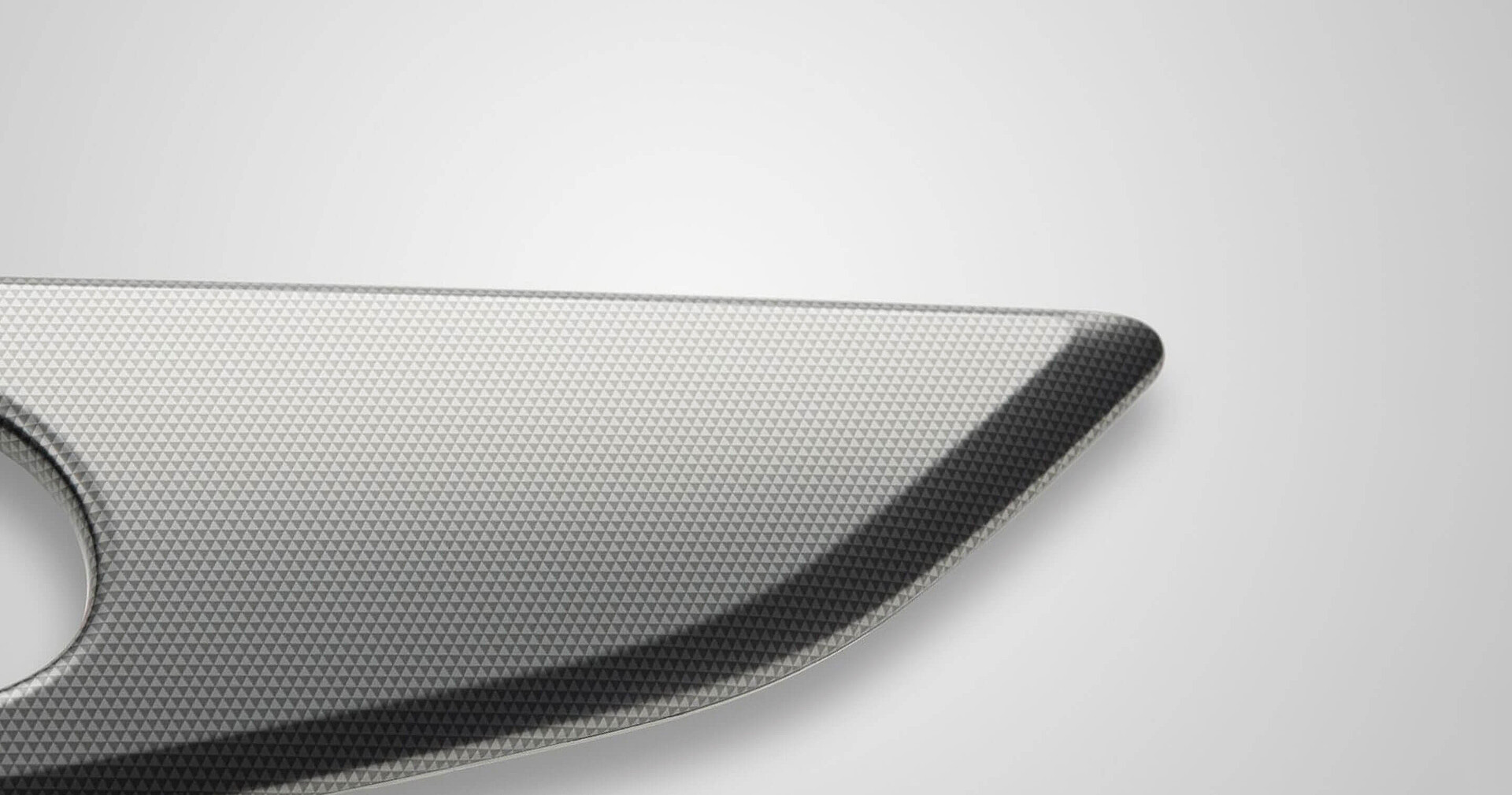

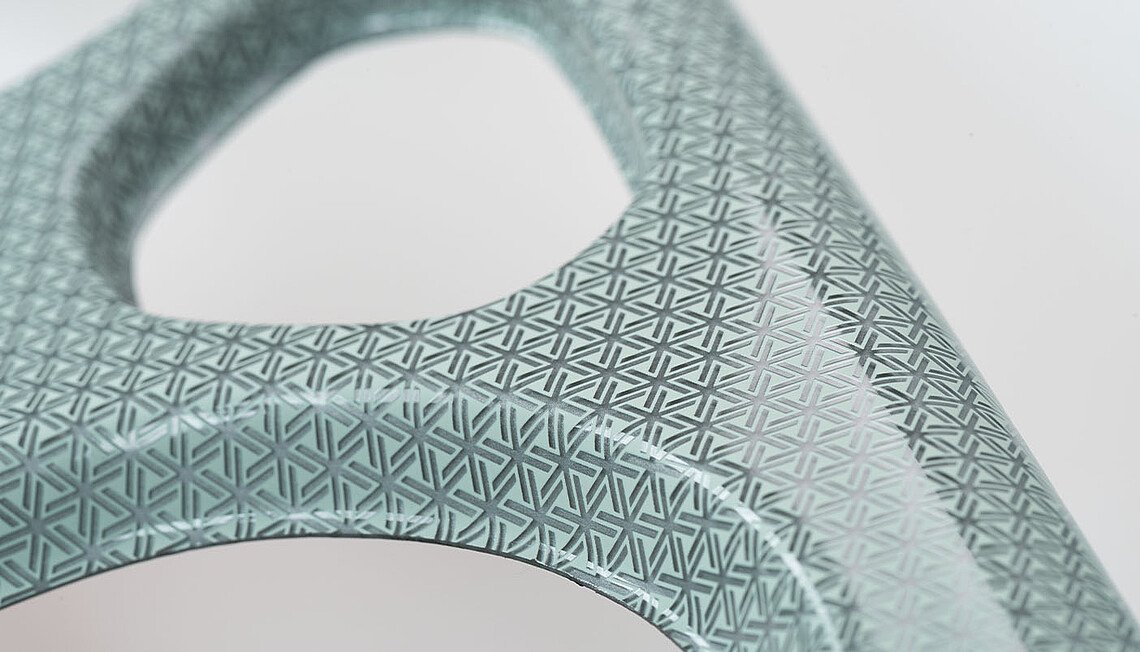

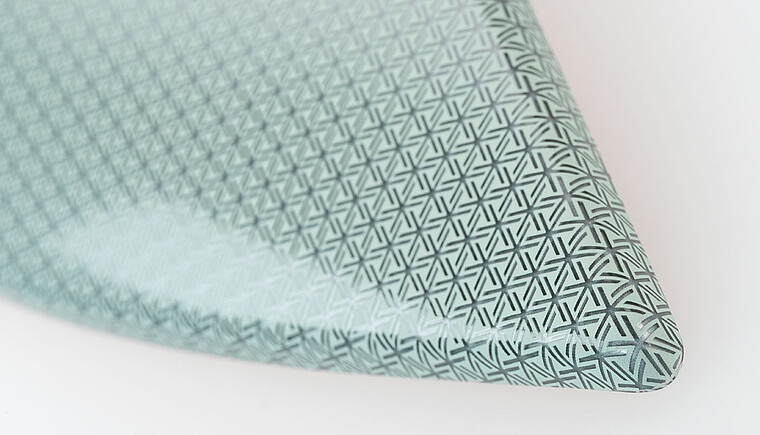

They are then deformed, punched out and back-injected according to the component geometry. This creates sensual and fascinating surface designs: Deceptively real depths and matte/glossy effects as well as tactile haptics that are second to none.

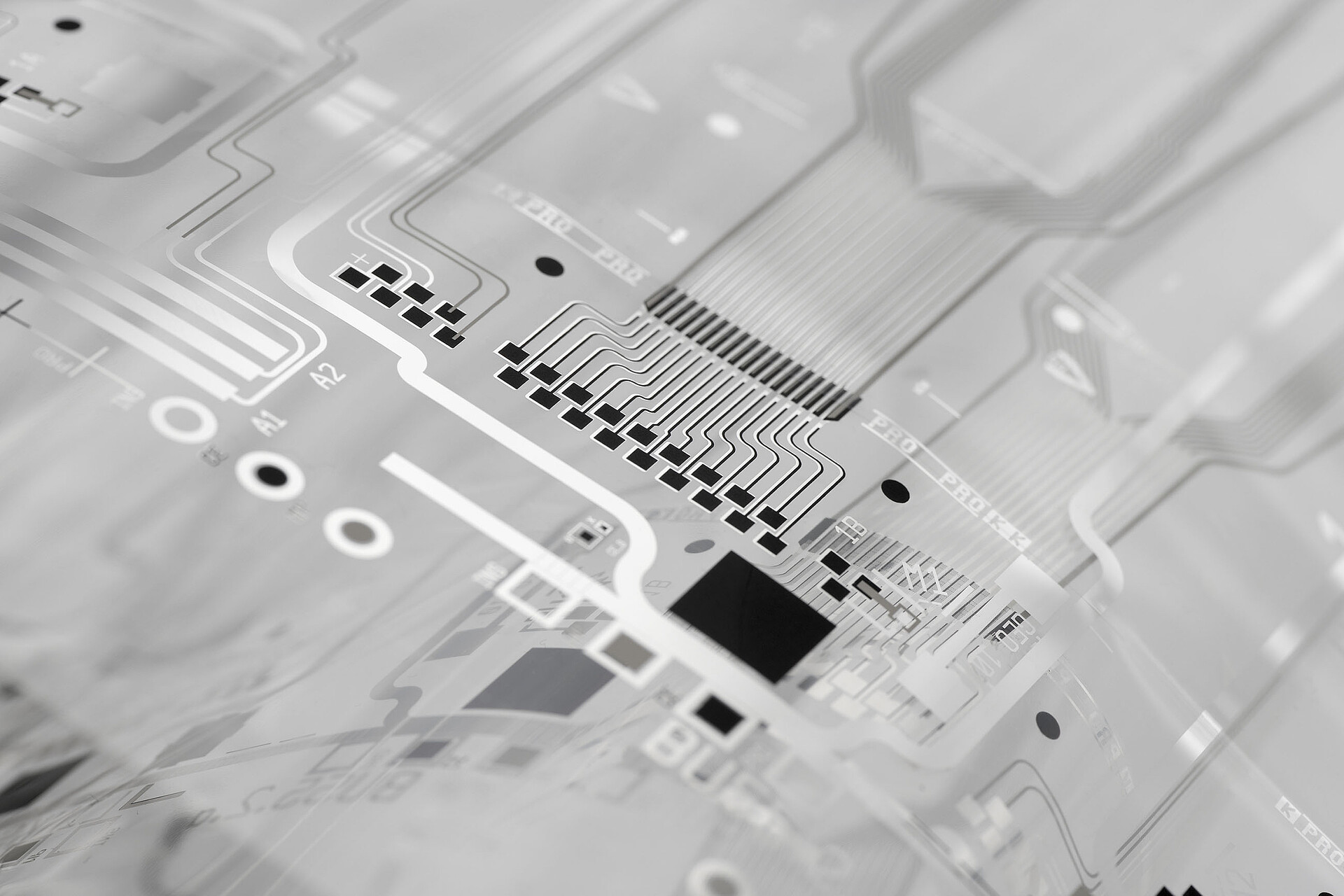

We can also enhance these surfaces by integrating wafer-thin, capacitive touch sensors from the KURZ subsidiary PolyIC.

Advantages of KURZ PMD:

- Spectacular effects; can be combined with many functions

- Suitable for extreme geometries

- Haptic designs feasible

- Recyclable surface design

- Suitable for recycled materials