Case Studies

- Fridge InteriorPDFInnovative refridgerator rear-panel, realized by using the hot-stamping process

- Greenling sustainable mini-gardensPDFMade of the post-industrial recycling compound RECOPOUND® by KURZ

- IMD for innovative hygiene dispenser designPDFInnovative design for the new ICON™series of Kimberly-Clark Professional™

- PolyTC® VarioSym sensorPDFHighly efficient and functional solution for touch panels

- In-mold decoration of household appliancesPDFResistant and robust surfaces with smart functions and customized design are created in just one process step

Decoration Processes - Videos

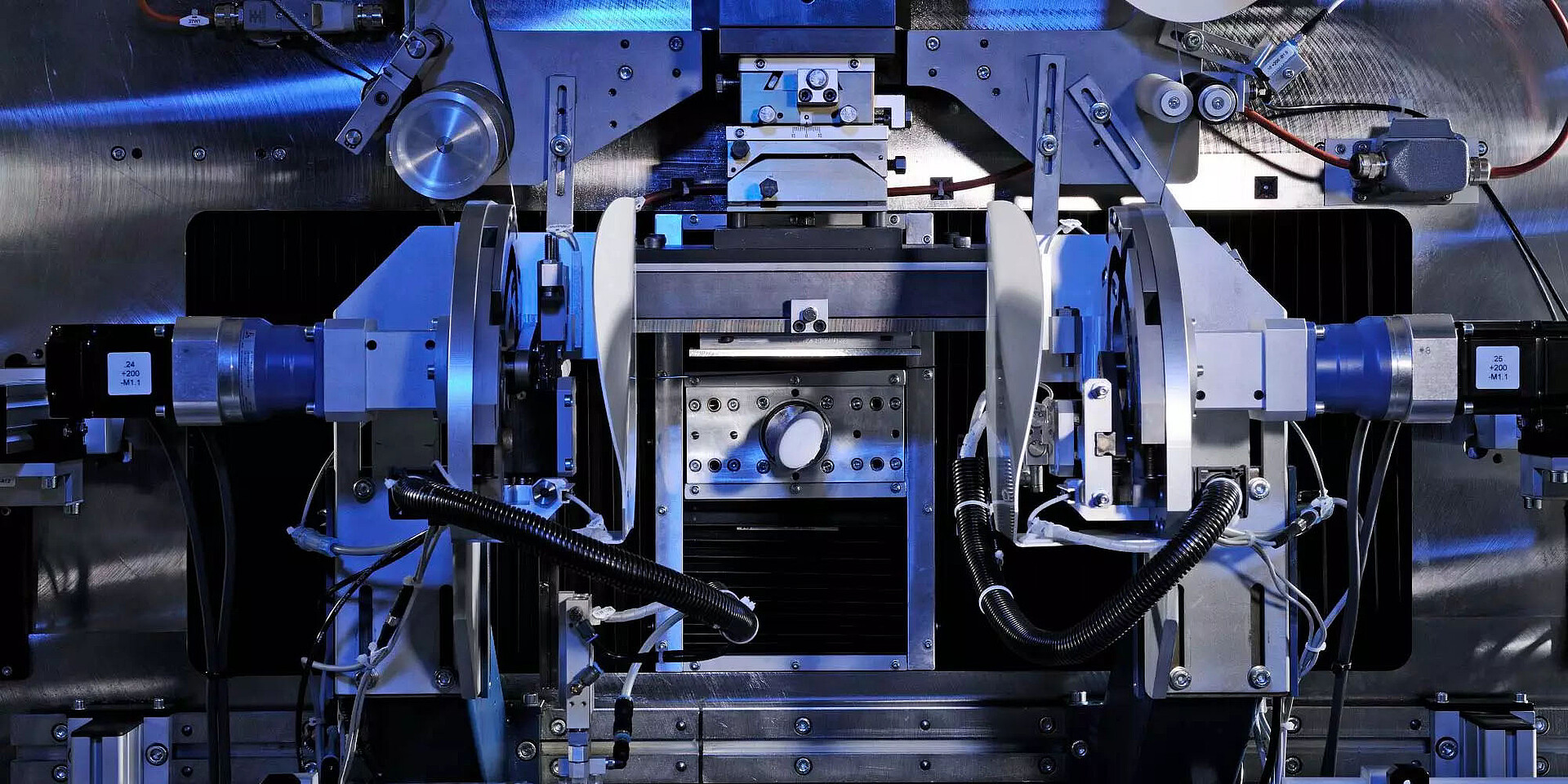

- Hot Stamping – Maximum precision for your plastic surface decorationYoutube-VideoTwo hot stamping process techniques can be used to apply decorations on two-dimensional surfaces of differently shaped plastic parts: vertical stamping and roller embossing.

- Hot Stamping PERFORMANCE+ Process on GEBA 8/1SYoutube-VideoThe new hot stamping PERFORMANCE+ process is implemented on the GEBA 8/1S – a machine from KURZ subsidiary BAIER, which is equipped with hot stamping dies from Hinderer + Mühlich (H+M, also part of the KURZ company).

- Hot Stamping PERFORMANCE+Youtube-VideoFor challenging geometries

- IMD: Perfect quality surface decoration for high volumesYoutube-VideoLEONHARD KURZ and its subsidiary BAIER present home appliances that blend design and functionality. Individualization, backlighting and touch functions: these are the trends of the future.

- IMD: Perfect quality surface decoration with laser engraving for backlighing effectsYoutube-VideoLEONHARD KURZ creates intelligent and distinctive designs for tomorrow. We focus on the current maga trends and bring sustainable and future-oriented surface solutions to life. E-mobility and autonomous driving: these are the trends of the future.

- IMD VARIOFORM® with Functional In-Mold Labeling (IML)Youtube-VideoKURZ has been awarded the 3rd main prize of the Bavarian Innovation Prize for the ‘IMD VARIOFORM® with Functional In-Mold Labeling (IML)’ process.

- Dual-component injection moldingYoutube-VideoLEONHARD KURZ is shaping the automotive exterior design of the future. Together with mold technologists from KURZ subsidiary Schöfer, KURZ the innovative high-efficency dual-component injection molding with IMD technology (In-Mold Decoration) makes it possible to realize a rear end cover concept part with a seamless, closed surface.

- Hot Stamping ProcessPDF, 4.30MB

- Print Mold Design (PMD)Youtube-VideoHigh quality decoration for 3D effect design

- KURZ decoration processes - Don’t limit yourself!Youtube-VideoExplore the vast array of possibilities for our innovative processes to produce eye-catching products with completely new and remarkable designs.

- KURZ - Machine Insight ServicesYoutube-VideoArtificial intelligence to enhance your machine services, shorten set-up times and increase efficiency: To provide you optimal support through the entire production process, our subsidiary KURZ DIGITAL have developed a new software especially for machines.

Brochures - PDFs

- BAIER digital printingPDF, 620 KBBe inspired by brilliant solutions!

- BAIER hot stamping processPDF, 318 KBTurning your creative ideas into reality

- CAP-tivate LuxuryPDF, 84.19 MBThe 'wow' for your design

- Dry chrome finishingPDF, 9.37 MBThe durable true-chrome finish on a roll - more than just a galvanic bath alternative. REACH compliant

- Heat transferPDF, 3.52 MBThe fastest and direct way to colorful diversity

- IMD for Soft-Touch surfacesPDF, 2.41 MBSurprising IMD effects for plastic surfaces

- IMD VARIOFORM®PDF, 2.37 MBOne-top process solution for the decoration of 3D shaped plastic components

- ISIMAT tube decorationPDF, 4.91 MBCustomized printing solutions for plastic tubes and jars

- PolyTC® sensor integrationPDF, 347.80 KBFreedom of function and design

- PolyTC® Touch sensorsPDF, 498.87 KBFor touching surface experiences