Displays for household appliances

Efficient and sustainable decoration using the IMD process:

An innovative joint project by LEONHARD KURZ, V-ZUG, Stöckli, and KraussMaffei

Challenge

Household appliances are much more than practical helpers today. They are smart and blend aesthetically into their surroundings. For manufacturers, this means combining surface resistance and robustness with smart features and individual design - in a single process step. This requires processes that combine the advantages of series production with options for custom solutions.

Goal

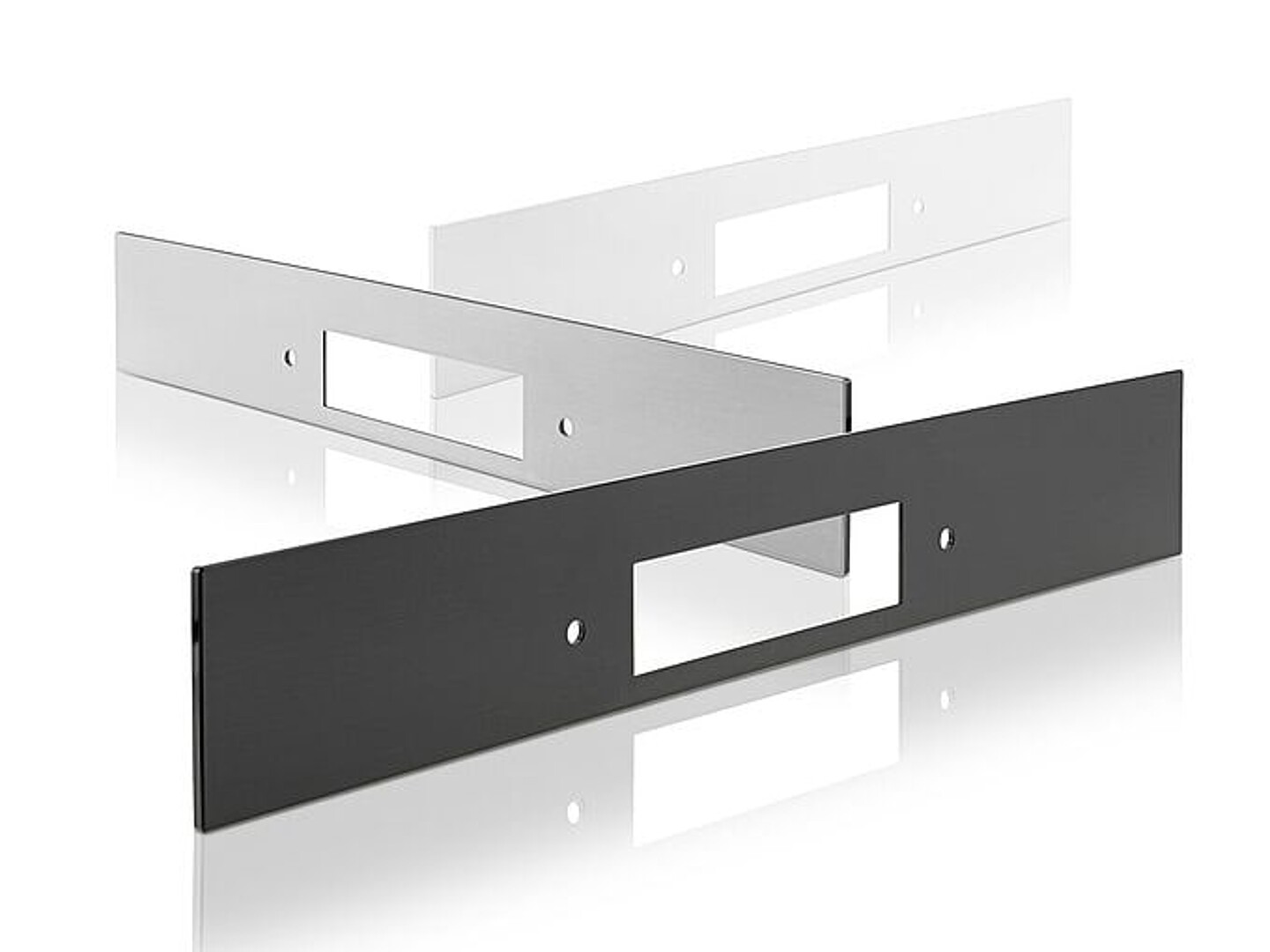

The Swiss company V-ZUG AG wanted to visually upgrade the control panel of their premium oven with three different decors and at the same time make the production more economical and sustainable. The desired result was a brushed metal surface made of plastic. In addition, the surface had to be resistant to heat and external influences such as cleaning agents. The solution to this challenge: In-Mold Decoration (IMD). In a single process step, the oven control panel is produced by injection molding, its surface is decorated, and, if desired, a conductive sensor film for touch operation is also applied to the back. The same process can also use recycled plastic with the same high quality as new material. This project was a premiere for the Swiss household appliance industry and at the same time the start of a new, sustainable production era.

Solution

V-ZUG AG brought three strong partners on board to implement this project: A. & J. Stöckli from Switzerland produced the oven control panel using the IMD process with an injection molding machine from the Munich company KraussMaffei. KraussMaffei developed a cell solution for the machine that enabled the oven panels to be made in a low-particle production process, creating a flawless operating surface. The three different panel decoration versions could easily be implemented in series production. LEONHARD KURZ developed the individual IMD surface designs, the tools, and the foil feed for the injection molding machine.

The foil feed device guides the IMD carrier material through the injection molding tool. The injection molding material presses the IMD carrier material into the cavity, and its temperature ensures that the decorative layer detaches from its carrier and connects to the plastic part. This means that when a KURZ IMD product is used in the decoration process, only a very thin layer of metal or varnish is applied to the product, and the recyclability of the decorated product is in no way impaired. There are no subsequent decoration, intermediate stock, or further work steps, which makes the process more economical and sustainable.

In addition, IMD can combine innovative designs with intelligent functions. The dead-front effect then creates elegant, homogeneous surfaces, which conceal the integrated touch functionalities. It is only through backlighting that the panel reveals how much smartness it contains. KURZ applies the functionalities via conductive sensor foils from the KURZ subsidiary PolyIC, which can be integrated using functional In-Mold Electronics (IME) during the same injection molding process. The decisive advantage is that custom finishing can be realized with the advantages of series production.

Why KURZ IMD decoration is the right solution for V-ZUG

- An efficient process suitable for series production, with which up to four different designs can be produced simultaneously

- Suitable for using recyclables

- Backlit panels for innovative design

- Panels with extremely hard-wearing surfaces

- Wide variety of surface designs possible

- Smart functions can also be applied using sensor foils in the same process step

Conclusion

Strong partners who work together professionally and efficiently, as well as innovative and intelligent surfaces, are the recipe for success for the latest household appliances, which let manufacturers score points with customers and strengthen their market position. Since the IMD process enables injection molding and decoration in one step and is also suitable for recycled plastic materials, decoration processes are more efficient, more sustainable, and suitable for series production. V-ZUG AG was so enthusiastic about the joint project that it would like to bring further devices to the market using this same process.