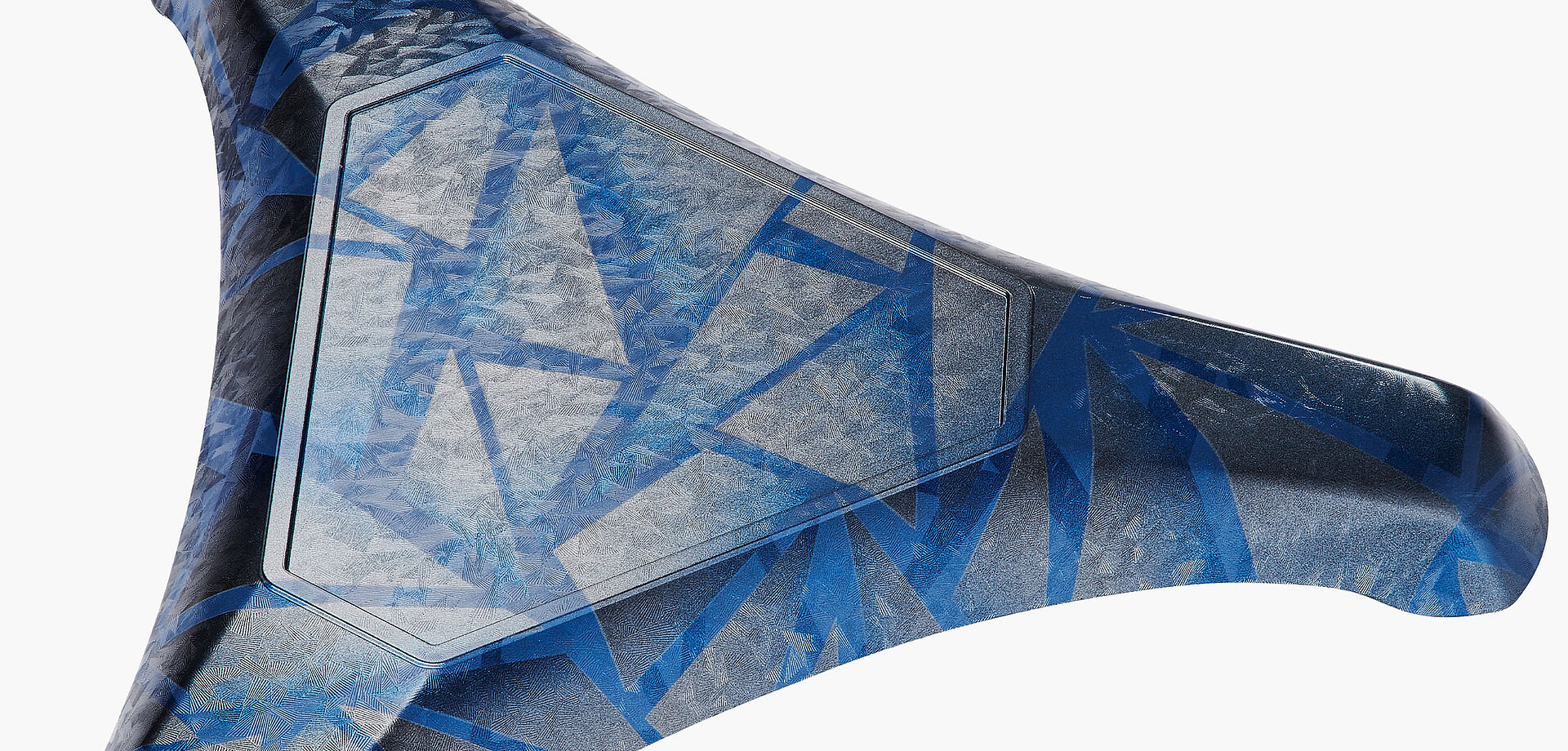

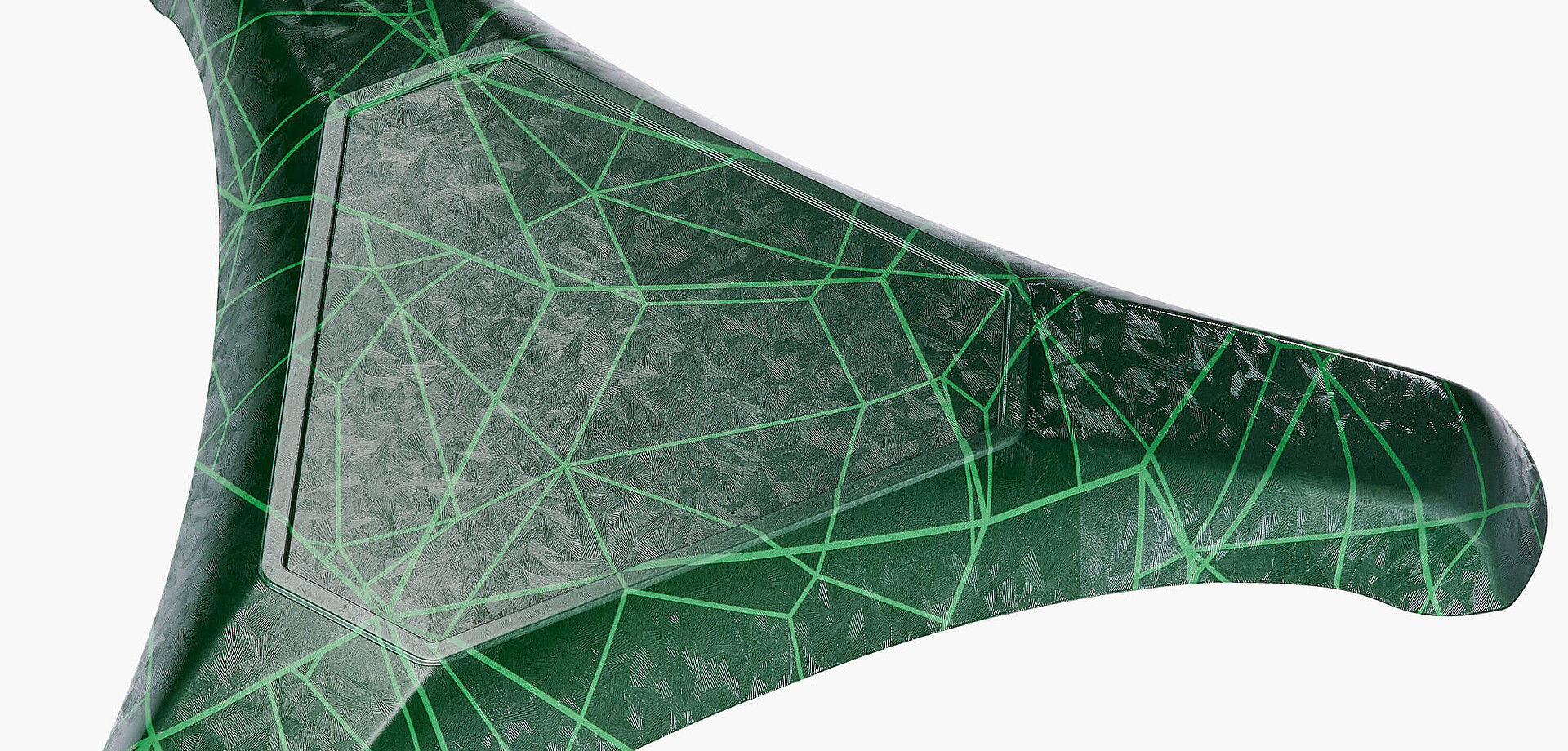

IMD VARIOFORM®

IMD VARIOFORM® from KURZ redefines the production of 3D components and has already been honored with the Bavarian Innovation Award. This process combines four techniques in one production step: Decorating, thermoforming, back-injection, and punching. This significantly reduces your carbon footprint. Full-surface or partial backlighting is also possible, as is the integration of touch sensors from the KURZ subsidiary PolyIC.

The IMD VARIOFORM® process:

- In the roll-to-roll process, the IMD VARIOFORM® carrier material with the decor runs through the machine

- The coating is heated directly in the injection mold and pressed into the recess of the tool. This gives the component its later shape, including a precise-edge surface design

- The blank is then back-injected in a stable manner

- Finally, the decorated component is punched close to the contour and can be processed directly

The advantages of IMD VARIOFORM® at a glance

- Decoration methods for extreme geometries

- Integration of touch sensors possible with IME decoration

- Backlighting and light design for special effects, partial or full-surface

- Variety of decoration options

- Decor is recyclable

- Also suitable for recycled materials

- Extremely efficient thanks to the combination of four production steps in one pass

- Reduced carbon footprint due to the combined process

- Small series and special editions can be realized economically