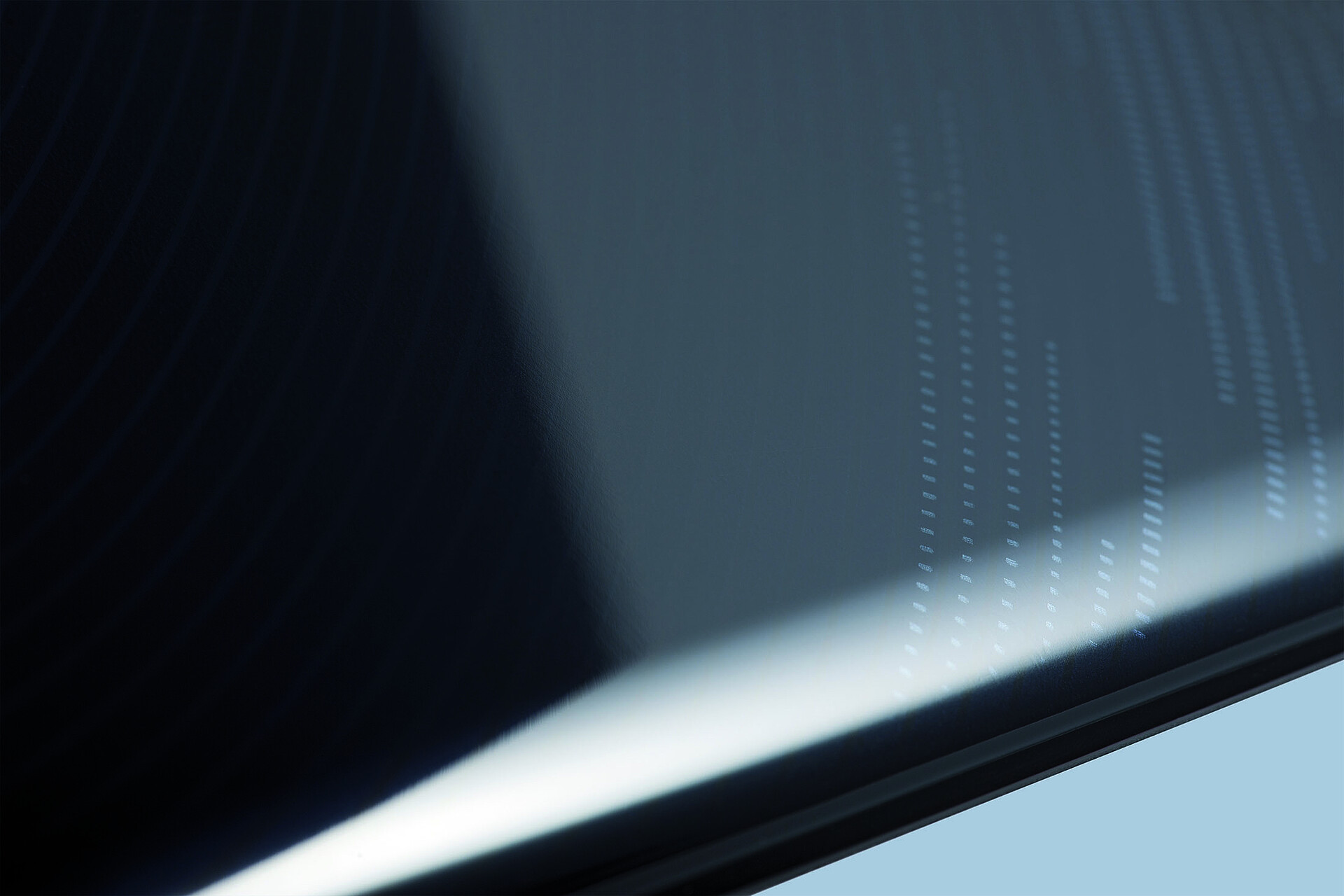

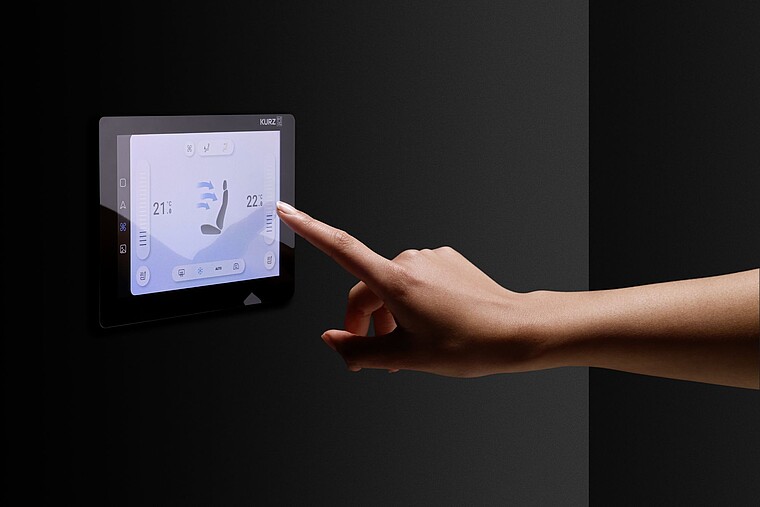

In-Mold Electronics (IME)

Combining efficiency and design

With In-Mold Electronics (IME), KURZ offers a pioneering solution for the decoration and simultaneous integration of PolyTC® sensors. Plastic parts for consumer electronics or household appliances, for example, can be decorated in one step and provided with smart touch functionality. This process shortens the value chain and saves energy, leading to a better carbon footprint. Strengthen your market position with KURZ as your partner - from the first idea to the integrated process solution.

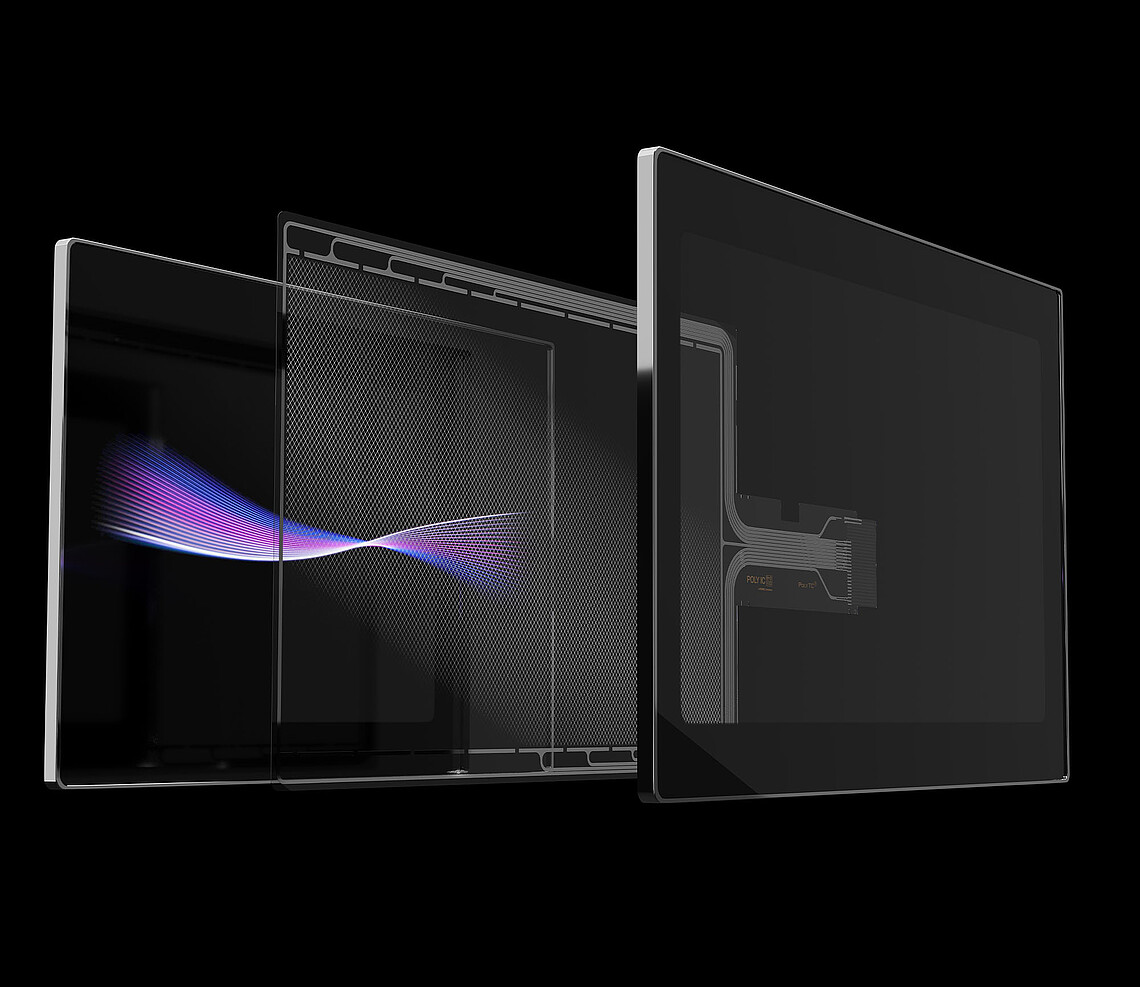

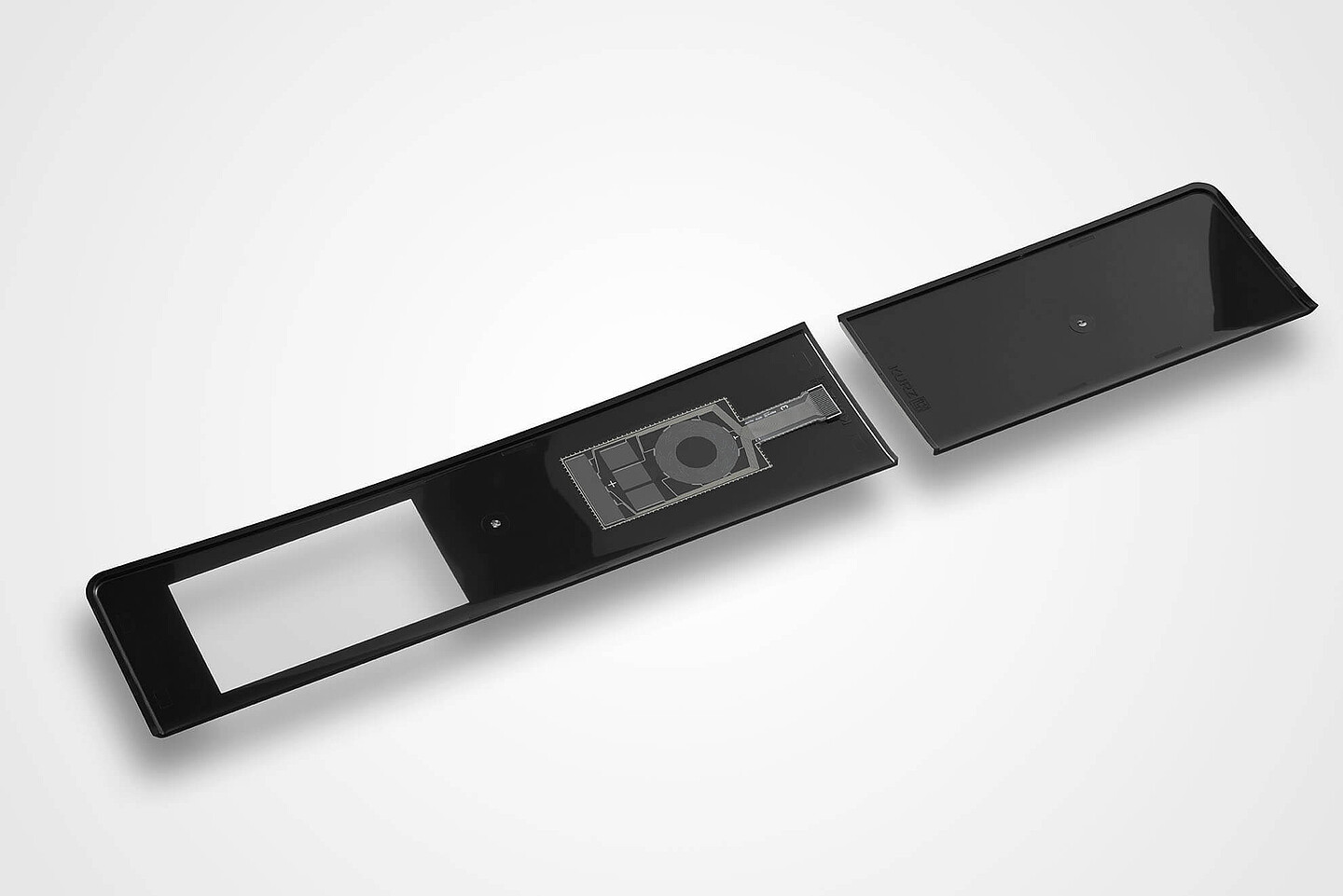

IME step-by-step

- Preparing the tool: The carrier material with the decorative coating for the later front side of the component is placed on one side of the tool

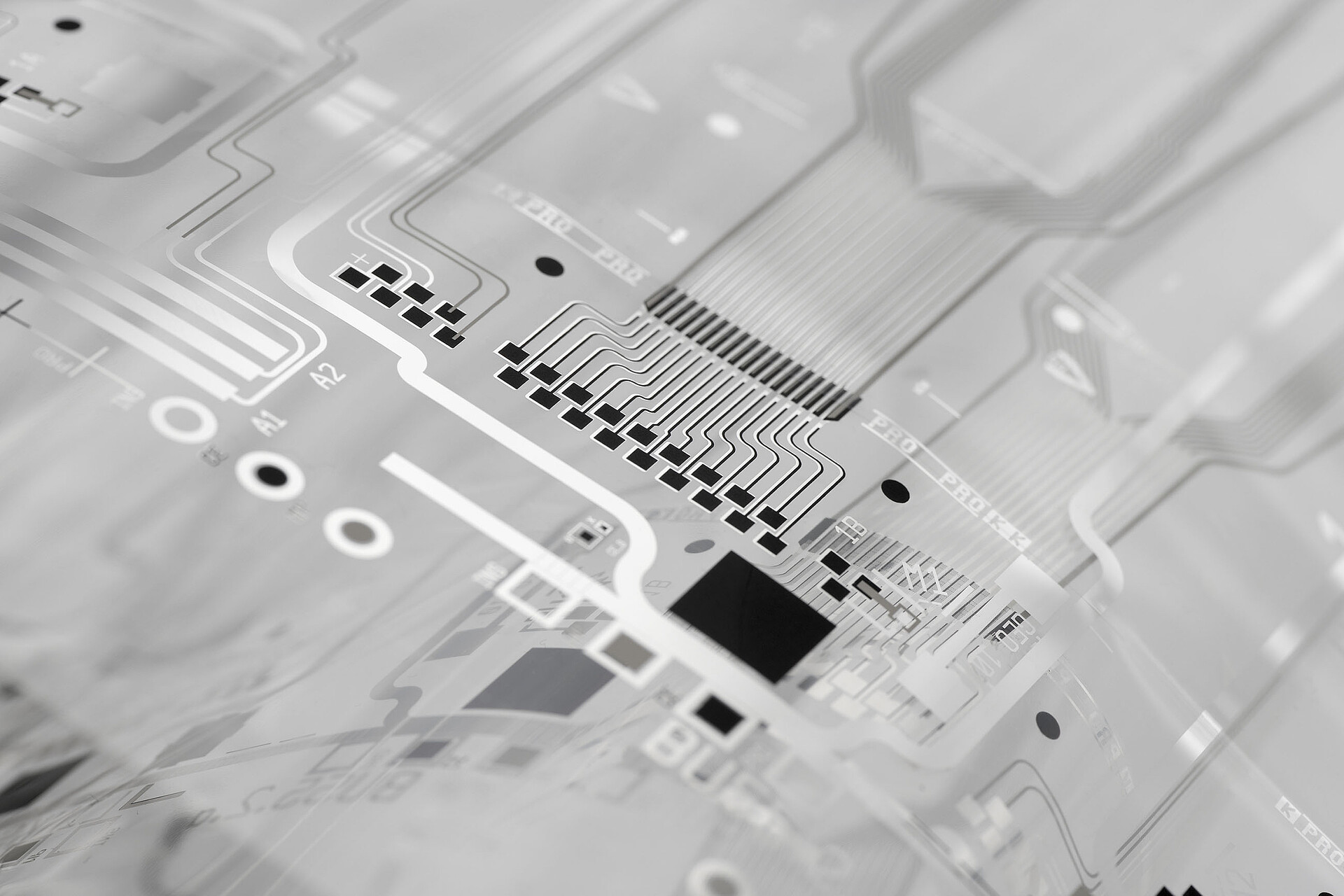

- Inserting the sensors: At the same time, the tool is inserted on the opposite side with the PolyTC® sensor label

- The tool is closed

- Injection molding: During a precisely controlled injection molding process, the component is formed with precisely dosed heat and pressure, the decoration is applied to the front part, and the sensors are integrated on the rear side. A special formulation from KURZ guarantees the stable adhesion and functionality of the sensors

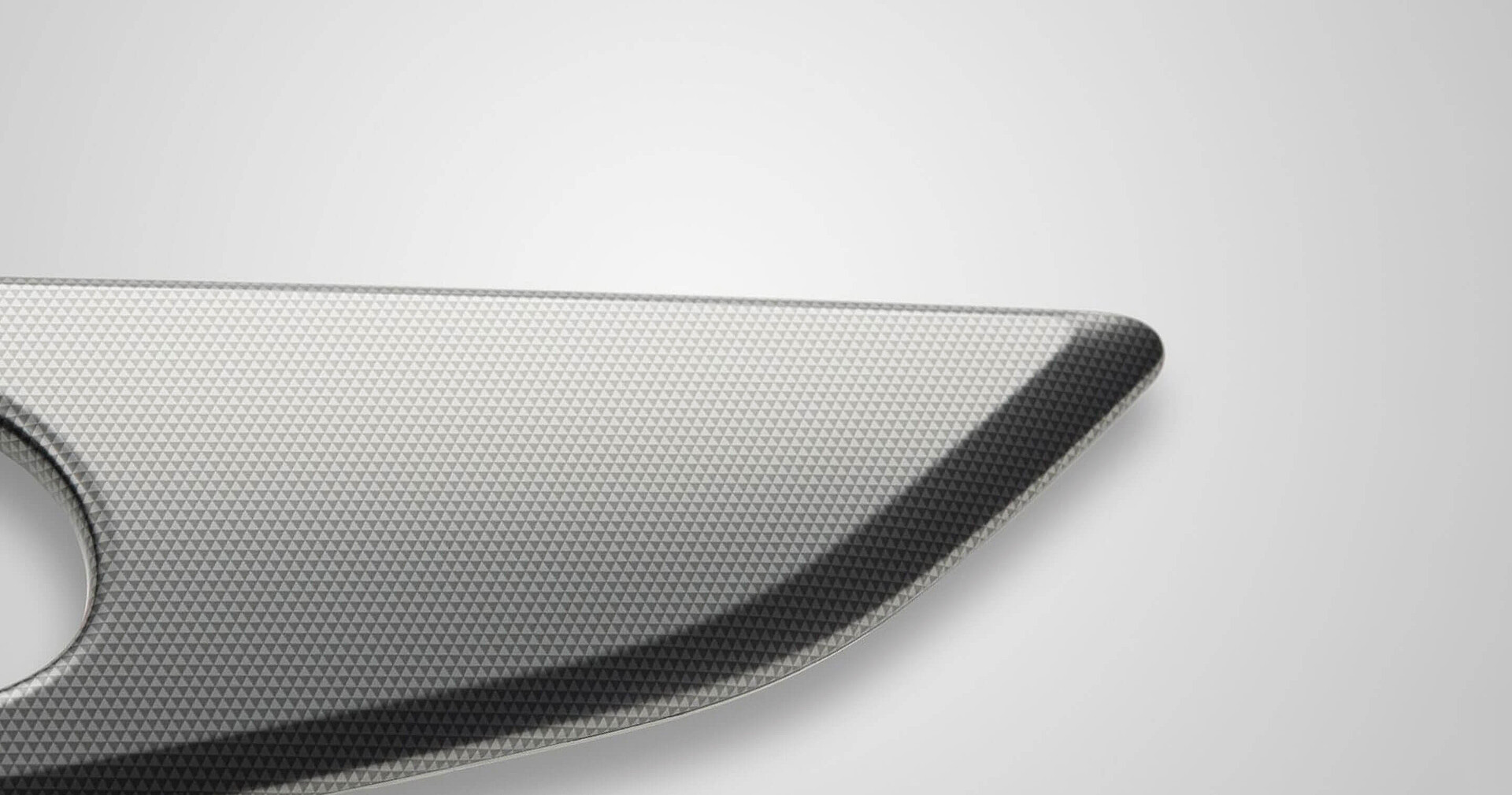

This process offers you a wide range of options. You can design 2D or 3D-shaped product batches, apply additional decors, or integrate sensors even without a front design.

Smart and sustainable

KURZ places great importance on sustainability: The IME process significantly reduces CO2 emissions, does not require energy-intensive post-drying, and enables the use of recycled materials without compromising the recyclability of the end products. The wafer-thin sensors reduce weight and replace conventional switches, while a wide pallet of surface decorations, backlighting or metallization can be realized. Discover the possibilities of IME for your plastic decoration projects.