Rely on RECOPOUND®

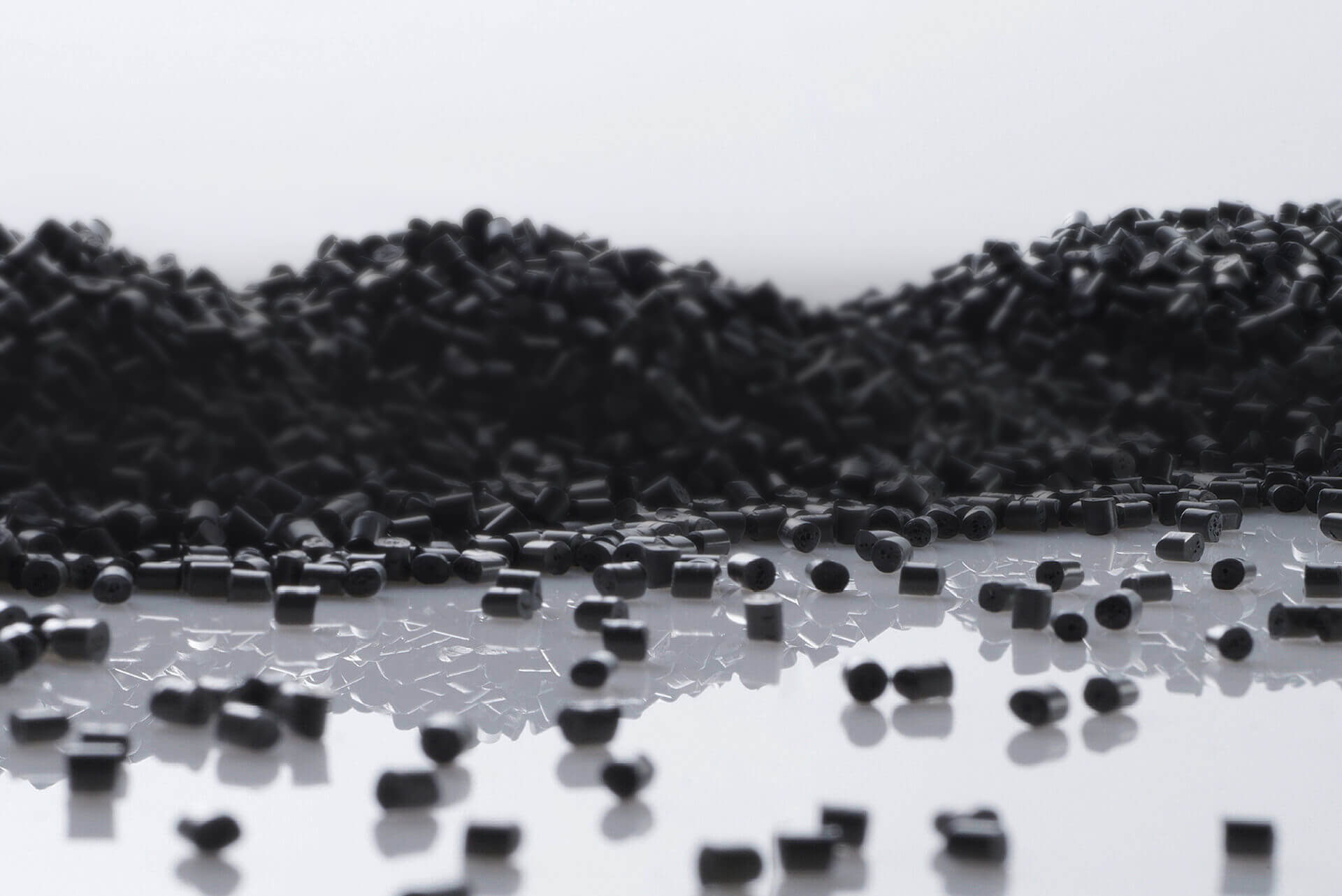

RECOPOUND® – Recycled compound based on PET

LEONHARD KURZ is the first company in the industry to produce high-quality recycled pellets from production residues: RECOPOUND®. With its optimized mechanical and visual properties, RECOPOUND® is suitable for the production of your injection molded parts, with outstanding results in workmanship and design.

RECOSYS® – When recyclable materials become something new

This development brings us another step closer to the circular economy: We recover our customers' PET transfer carrier residues and process them into granules in a specially developed procedure that we optimize specifically for using in injection molding. This material can be used for stable and robust products, and decorated to a high standard.

Your advantages

- Up to 40% less CO2 consumption compared to production with virgin material

- RECOPOUND® can be processed excellently in injection molding

- Transparent ingredients without conflict materials

- Stable end products

- Numerous decoration options

- Decoration of the recyclate does not affect recyclability

- Products made from this granulate can be recycled again

- We produce with renewable energy from our own resources

Possible application areas for RECOPOUND®

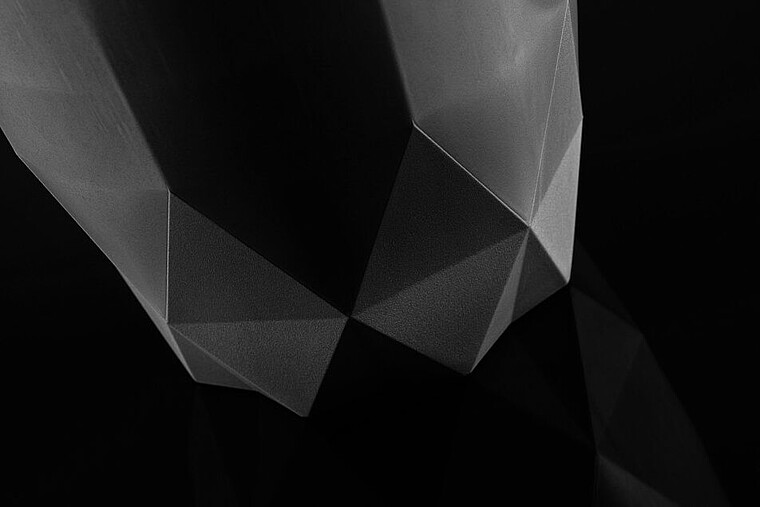

Whether as sturdy transport and storage boxes, household goods or garden furniture, RECOPOUND® is suitable as a construction material for robust plastic products from a wide range of industries.

In addition to our recyclate itself, we also offer you the full spectrum of KURZ plastic decorations for visual enhancement of your product. Its recyclability is not restricted by the finishing. This makes us the only provider that can offer material delivery and decoration in one complete package.

How does RECOPOUND® affect my environmental footprint?

Thanks to our innovative KURZ RECOSYS® recycling program, up to 40% of CO2 emissions are saved in the production of RECOPOUND® compared to virgin material production, as recycling eliminates the upstream processes for virgin PET. At the same time, resources from transfer products flow into RECOPOUND® and do not have to be used for energy recovery. Both have a direct impact on your environmental footprint.

Scope of delivery & service

We deliver RECOPOUND® as ready-to-use pellets, allowing you to start production directly. Our recycling experts will be happy to advise you on-site and support you in your first steps to sustainable production directly at your machine. Our service team impresses with its unique expertise in tool making and production-related consulting.

RECOPOUND® as part of the KURZ recycling program

With RECOPOUND®, we are closing the recycling cycle of our production: From production to application and recycling of the carriers for our transfer finishes, we have sustainably optimized our process. This requires our unique KURZ RECOSYS® return and recycling system for PET transfer carriers. This is based on close cooperation with our customers in the graphic industry. Thanks to our cross-industry expertise, we are able to secure these recyclables and keep them in the usage cycle with an innovative reprocessing process. The result is high-quality, injection-moldable pellets for your sustainable products: RECOPOUND®. We also obtain all of the electricity at our sites in Fürth and Sulzbach-Rosenberg from renewable sources. The purchased green electricity is replenished with self-generated energy, e.g. from photovoltaic systems.

It goes without saying that we make our production chain as transparent as possible for you. This gives you the certainty that the ingredients of our compound are 100% traceable. We are continuously working on expanding our recycling.